Packaging Mistakes to Avoid for E-Commerce Brands

Packaging shapes your customer’s unboxing experience, protects products during delivery, and influences how your brand is perceived online. E-commerce businesses, big and small, must pay close attention to packaging details to minimize losses, reduce returns, and increase customer satisfaction. This article discusses common packaging errors e-commerce brands should avoid and how working with experts like Zee Custom Boxes UK can help your brand succeed.

Zee Custom Boxes UK: Redefining E-Commerce Packaging Standards

As the online retail landscape evolves, solutions like Zee Custom Boxes UK provide a range of packaging options and guidance to help brands optimize both the safety and presentation of their goods. Without professional insight, brands often repeat preventable packaging mistakes that can negatively impact their reputation and operations.

Using Inappropriate Packaging Material

Inappropriate materials can compromise product integrity, inflate costs, or frustrate customers, often leading to higher returns and poor reviews.

Insufficient Protection

Many brands underestimate the rigors of shipping. Thin, flimsy boxes or unsuitable fillers can leave products vulnerable to breakage. Electronics, glassware, and cosmetics need sturdy packaging and internal padding. Brands should select boxes with the strength and cushioning suited to their product’s weight and fragility.

Over-Packaging

Using excessively large boxes or too many fillers increases shipping costs and wastes resources. Customers are increasingly mindful of environmental impacts, and excessive packaging may cause dissatisfaction or negative feedback. Choosing right-sized packaging minimizes waste and shipping fees.

Using Non-recyclable Materials

With sustainability in focus, brands relying on non-recyclable packaging risk alienating eco-conscious consumers. Using excessive plastic or hard-to-recycle composites diminishes brand value and environmental responsibility.

| Packaging Material | Impact on Product | Environmental Impact | Customer Perception |

|---|---|---|---|

| Strong corrugated box | Good protection | Widely recyclable | Positive |

| Thin folding carton | Poor protection | Varies | Negative if product damaged |

| Biodegradable filler | Good protection | Positive | Positive |

| Bubble wrap | Good protection | Limited recyclability | Mixed |

Ignoring Brand Presentation

Packaging is a powerful branding opportunity. Overlooking brand presentation can limit repeat purchases and customer loyalty.

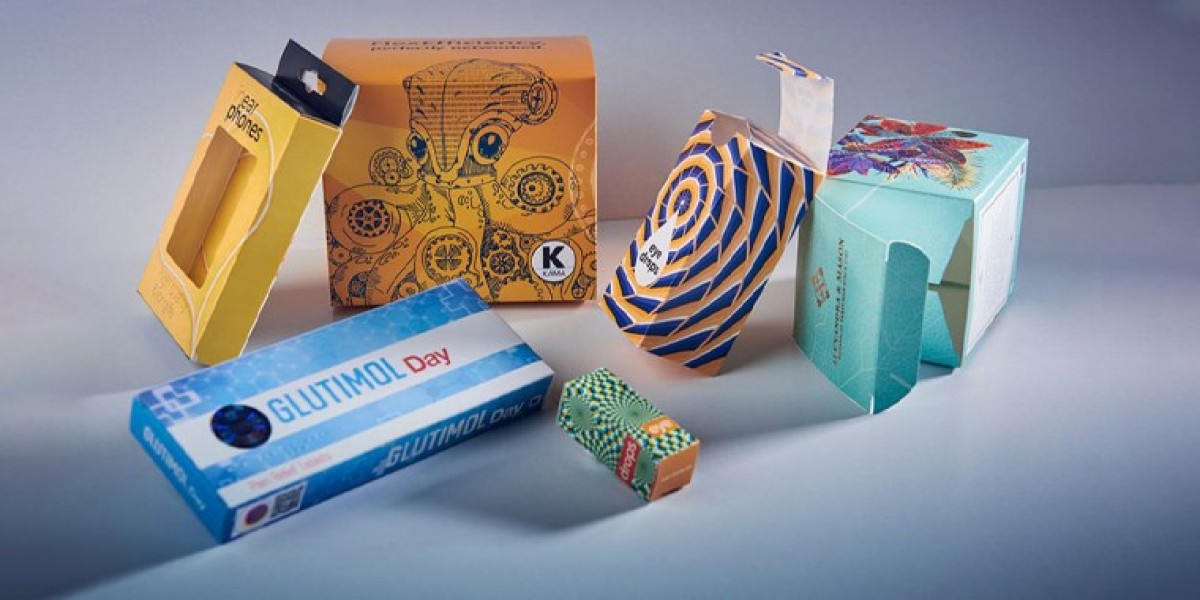

Generic Boxes

Plain, unbranded boxes are missed opportunities for brands to reinforce identity and create excitement. Bespoke packaging helps your order stand out and generates organic social media buzz from unboxing content. Even simple branded stickers or colors enhance memorability.

Poor Print Quality

Faded logos and unclear print reduce the perceived quality of the entire order. Investing in high-quality print and finishes on packaging ensures your logo, colors, and information remain sharp and appealing from warehouse to doorstep.

Inconsistent Brand Messaging

Including inconsistent graphics or mismatched packing slips creates confusion and dilutes the shopping experience. Always coordinate design and messaging across every packaging element to reinforce trust and professionalism.

| Brand Element | Impact on Customer | Resulting Experience |

|---|---|---|

| Branded packaging | Recognizable | Positive, memorable |

| Unbranded packaging | Anonymous/Generic | Forgettable, ordinary |

| Consistent colors | Cohesive | Professional look |

| Mismatched slips | Confusing | Unprofessional |

Failing to Prioritize Secure Sealing and Labeling

Orders lost or delayed due to poor sealing or errors in labeling cost brands both money and trust.

Inadequate Sealing

Weak tape, loose flaps, or unreinforced seams can lead to packages opening during transit. Products may arrive damaged, or go missing, resulting in extra costs and frustrated customers. Strong adhesive tape and multi-point sealing are essential.

Missing or Incorrect Labels

Mislabeling causes misdeliveries and delays. Always double-check addresses, barcodes, and content details before dispatch. Automated labeling systems can enhance accuracy, especially at higher order volumes.

Lack of Important Information

Failing to add clear “fragile,” “keep dry,” or “this side up” messages can result in rough handling. Proper labeling alerts couriers and helps reduce claims.

| Sealing/Labelling Issue | Effect | Potential Outcome |

|---|---|---|

| Weak tape | Packages open in transit | Damaged/missing items |

| Wrong addresses | Sent to wrong location | Lost order |

| No handling cues | Mishandling | Breakage, complaints |

Poor Consideration for Returns and Reuse

E-commerce relies heavily on hassle-free returns. Brands often overlook return-ready packaging, creating inconvenience for customers and loss of future sales.

Difficult-to-Open Packaging

Overly complicated or tightly sealed boxes frustrate recipients. Easy-open tear strips or perforations show consideration for the customer’s convenience.

No Return Feature

If a customer wants to send a product back, making it difficult to reuse the original packaging adds to their dissatisfaction. Features like self-sealing strips, return labels, or resealable bags make returns smoother.

Non-reusable Internal Packaging

Packing materials that can’t be repurposed for a return put the burden on the customer, increasing waste and lowering satisfaction.

| Return-Friendly Feature | Benefit | Customer Experience |

|---|---|---|

| Easy-tear strips | Easy opening | Positive |

| Resealable bags | Simplified return | Convenient |

| Return label inside | Fast return process | Appreciated by buyers |

Neglecting Packaging Cost and Logistics

Excessive spending on packaging, or ignoring shipping constraints, harms the bottom line and can cause operational bottlenecks.

Choosing Luxury When Simple Suffices

Not every product needs deluxe packaging. Allocating higher budgets where the customer expectation is minimal adds unnecessary expense without ROI.

Overlooking Dimensional Weight Charges

Larger packaging than necessary increases shipping costs due to dimensional weight calculations from carriers. Carefully matching box size to product size controls expenses and is more eco-friendly.

Poor Storage Considerations

Bulky or non-collapsible packaging complicates warehouse storage, takes up more space, and increases overhead costs.

| Logistics Decision | Impact | Result |

|---|---|---|

| Oversized packaging | Higher shipping costs | Reduced profits |

| Right-sized packaging | Lower shipping costs | Improved efficiency |

| Non-collapsible boxes | Storage challenges | Wasted warehouse space |

Disregarding Sustainability Concerns

Modern consumers want eco-friendly packaging. Brands ignoring this trend risk losing loyal customers to more sustainable competitors.

Excessive Packaging Waste

Shipping small items in large boxes or using non-biodegradable fillers leads to excessive waste. Customers expect brands to use only as much packaging as necessary.

Not Communicating Green Initiatives

If your materials are eco-friendly, state it clearly on the packaging. Failing to highlight green efforts is a missed opportunity to impress environmentally conscious buyers.

Ignoring Regional Recycling Regulations

Sending packaging that is not recyclable locally can frustrate customers and create disposal problems. Research regulations in target markets to ensure compliance.

| Sustainability Practice | Consumer Appeal | Long-term Benefit |

|---|---|---|

| Minimalist packaging design | Positive | Reduces costs, waste |

| Eco-friendly materials | Positive | Improves reputation |

| No recycling info provided | Negative | Missed opportunity |